"Premium stones" metal nameplates are custom made, metal etching is the method of making nameplates from metal.

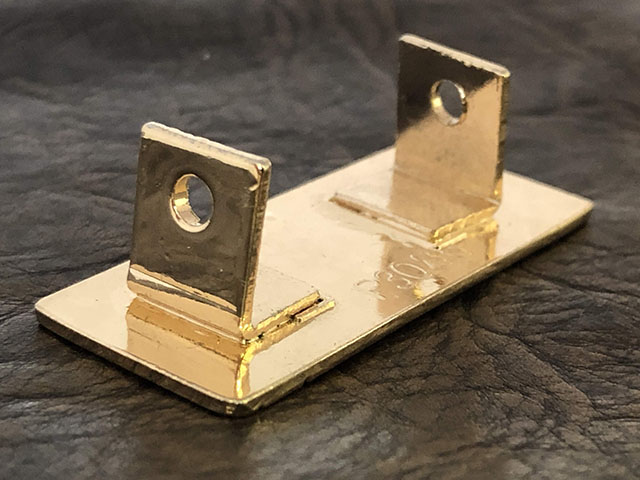

| schild size | 60 x 20 mm |

| brass | copper alloy material |

| coating | nickel, gold |

| clutch | double-sided tape |

Manufacturing of metal plates, nameplates for diaries, bags, furniture, household and org. equipment, Schild for cars with various types of fastenings.

All sources (logo, layout) are accepted only in vectors, in formats: Adobe Illustrator (eps, ai), or in pdf.

If your designer independently develops the layout of the future product, he must receive advice from the manufacturer on technological limitations. The main restrictions include the minimum radii of the contours of the schild contour, the minimum thickness of the metal line separating enamels, and some others.

The main thickness of the lines:

the thickness of the protruding line must be not less than 0.3 mm, depressed not less than 0.2 mm, the thickness of the external side is not less than 0.4 mm. This information will allow you to accurately express your idea in the product.

Depending on the image, circulation, budget, customer requirements, our company uses three main technologies for the production of metal plates, nameplates, labels, emblems:

Photo engraving (etching) is the most basic and widespread method of manufacturing linings with a flat two dimensional relief image (2 D). The advantages of this technology, high accuracy of the transfer lines of the figure - the sketch, the speed of the order, not a high price for small and medium editions. The recommended circulation from 100 pieces.

The process of manufacturing linings by etching:

The photo-image is transferred to the metal with the applied photosensitive layer, manifested and subjected to chemical treatment. The acid dissolves the metal unprotected by the emulsion to the required depth, forming indentations into which the enamels will be applied. After the metal blanks have found relief, they use a special press to cut out the plates of the required shape. Then the blanks are covered with a thin layer of decorative coating by electroplating gold, nickel, copper plating. After, the lining is painted with cold colored enamels, then, the surface of the lining can be coated with epoxy resins (polymer resin - lens).

Stamping (embossing) is a classic method of manufacturing linings. The stamping technology allows to transmit a three-dimensional relief image with a strongly pronounced relief and volume (3D). This technology is used, with runs of 2000 pieces and more, the use of stamping with small runs is not advisable, because of the high cost of manufacturing 3 D models, a set of snap-ins and deadlines.

The process of manufacturing linings by stamping:

The engraver manufactures a master model, on the basis of which the tooling is done: a stamp (molding matrix) and a die stamp. After quenching, the molding matrix is placed on the stamped press and on it, with a force of about 100 tons, the plates are made of soft metals (copper alloys). The minted leibs on the scouring press are cut down along the contour and a hairpin is attached to them. Then decorative electroplating is applied: gold, nickel, copper. After electroplating, colored enamels are applied to the resulting depressions.

Milling is a three-dimensional engraving method. Milling allows you to make clear geometric shapes, transfer the volume and relief comparable to stamping - chasing. This technology is used when it is necessary to manufacture small editions of 1 - 100 emblems with a three dimensional relief 3 D image.

The essence of the method is that with the help of special computer programs an exact drawing of the product is made, both in a two-dimensional plane and in volume. Then the image is transferred to a three-dimensional milling software machine that cuts the overlay.

Since the production of linings, nameplates, labels, emblems, mainly copper alloys (copper, brass) are used, which oxidize under the influence of oxygen, the metal must be protected. For this purpose, various types of decorative electroplating coatings are used: nickel plating, gilding, silver plating, copper plating, chrome plating, the coating not only protects, but also makes it possible to produce bright metal lining, the surface of which can have a brilliant, matte, antique - antique look of products.

The main coatings used on the linings by our company are: gold, nickel, brushed nickel, black nickel (bluing effect), copper plating, chrome. Antique Effect Coatings: Blackening of Brass, Copper:

Galvanic coatings on metal products are a thin layer of another metal that has anti-corrosion properties, weather resistance and good aesthetic data (for example, nickel, chromium, gold). The thickness of such a coating can be from fractions of microns to tenths of mm.

Color enamels:

To make the metal lining more vivid and attractive, in the manufacture, we use colored enamels and varnishes, allowing to obtain various effects on the lining.

Enamel is applied to the grooves of the lining, manually with a special syringe. This is a time-consuming process that requires an enamel work experience and specific knowledge. After applying the product with enamels undergoes heat treatment at a temperature of 70-90 degrees

Important! each computer screen displays the color differently, to get the most accurate color, you need to specify the color according to Pantone C, preferably in the process of preparing the icon layout, match the color of the color with the manufacturer, and even better align the enamels on the signal samples of the overlays, as enamels possess some transparency and on metal, their color can differ from color on paper or other carrier.

In this section, the main accessories, types of fasteners for linings, Schild, Label, emblems used for our products are presented.

All applied accessories for Schild, meets European standards of quality and safety, ensures reliable fastening and long service life of products.

Production of overlays, shild, tags, production of Schild, overlays, metal slips, tags, emblems, labels, shields to order Kiev:

Welcome to the page lining, shields - manufacturing. You are greeted by a friendly team of professionals, the team of an industrial enterprise manufacturing and manufacturing metal linings to order in Kiev - Image Grad.

Metal plates (nameplates) - nakladki-Schild: information plate (plate, nameplate, label, label) on which are inscriptions and symbols relating to the product.

Metal nameplates, metal plates are used: for marking, branding of branded goods - computers, household and video / audio equipment, cars, leather products, designer clothes, bags, factory equipment, for bottles, interior items, furniture, souvenirs in advertising and informational purposes.

With the help of metal Schild, linings, tags, you can present any information about a product, company, brand, product parameters, services.

Metal plates, nameplates, tags, emblems, labels, labels, have an advertising character, emphasize the corporate style and image of the company, increase brand or trademark awareness, emphasize individuality.

At the manufacturing plant Image Grad, for the manufacture of a plate, metal plates, emblems, tags, labels, labels, metal is used brass, copper, aluminum, steel. Metal nameplates, plates, brass tags, have durability and strength, resistance to mechanical damage, moisture, temperatures, chemicals.

The most common methods for the manufacture of metal plates and plates are etched, the etching method (2D image) and the cold stamping method (3D image), these manufacturing methods make it possible to obtain the production of linings, a sign plate with a wear-resistant, relief image.

Depending on the circulation of the nameplate, the complexity of the logo - emblem, relief, the method of production of metal nameplates and linings is selected, we consider the main ones:

Lining etching - lining photo engraving, the most common method of manufacturing flat lining - nameplates made of metal (chemical etching process). This method of producing nameplates and emblems makes it possible to manufacture nameplates with 2D relief, in the shortest possible time with small runs.

Organization of production of metal Schild and linings to order method of metal etching:

The designer performs a 2 D design of the Schild's layout, further, by a photo-method, the image is transferred to the metal with a photosensitive layer applied, manifested and subjected to chemical treatment. The acid dissolves the metal unprotected by the emulsion to the required depth, forming indentations into which the enamels will be applied. After the metal blanks have gained relief, on a special press, lining of the required shape is cut out of them. Then, the lining is covered with a decorative coating, a thin layer of gold, or nickel. After painting with cold enamels, the surface of the lining can be coated with epoxy resins - polymer.

Pads stamping - pads - embossing - a classic way of making pads and nameplates, where you need to transfer a strong relief and image size - nameplates, emblems with 3D relief. Production of linings - Schild of metal by stamping - chasing, involves a circulation of 300 pieces and a rather long production time of 20 - 30 working days!

Organization of production of metal nameplates to order by the method of cold stamping - metal embossing:

The designer performs the 3D model - Schild's layout, then, the engraver manufactures a master model, on the basis of which the equipment is made: a stamp (molding matrix) and a die stamp. After quenching, the molding matrix is placed on the hammered press and on it, with a force of about 100 tons, nameplates of soft metals (copper alloys) are stamped. Leaked nameplates, on a die-cut press, are cut along the contour and a pin is fastened on them. Then a galvanic decorative coating is applied: gold, nickel, copper plating, chrome, and after coatings colored enamels and varnishes are applied into the resulting depressions of the metal lining.

Depending on the desired result and the use of plates, metal nameplates, the products are coated with electroplated coating (gilding, nickel plating, copper plating, chrome plating), and also metal nameplates, lining are painted with cold enamels and varnishes, and for the most aggressive protection of the lining, nameplate is used polymer resin polymer (lens)

Types of mounting metal nameplates, metal linings:

Self-adhesive base on two-sided adhesive tape - the main application for cars, furniture, wood, products with a smooth, non-porous surface. After proper installation of the metal lining, the nameplate at the place of attachment, the product is not torn by any means.

Fastening pads on bending mustache - the main application for leather. haberdashery, cardboard production, textiles, soft materials, Schild with a mustache sits in the seat of the product, the mustache is bent on the back side of the lining.

The third type of fastening of plates and metal nameplates, holes for sewing, screw holes, screws or nails, rivets are the main application in the furniture and textile industry.

Since 2006, the manufacturing enterprise Image Grad, demonstrates the excellence of the manufacture of metal linings and nameplates using traditional and modern technologies for the production of metal linings, nameplates, emblems.

The Image Grad company has extensive experience in the development and manufacture of overlays, metal nameplate: overlays for diaries, overlays, nameplates, tags and labels on bags, backpacks, clothes, hats, shoes, overlays for household and org. equipment, metal plates, shields on furniture, linings, emblems on cars, lining on bottles, shields on leather. haberdashery with different types of mounts.

We accept orders for the manufacture of linings, nameplate made of metal, of any shape and complexity, production of linings, Schild according to individual layouts, applying modern technologies for the manufacture of linings, Schild: by etching, stamping, milling. Special galvanic coatings of overlays, nameplate are used: gilding, nickel plating, copper plating, chrome plating, which allow to produce original metal plates and nameplates, the surface of which may have a shiny, matte, old-looking product, depending on the customer's wishes.

To make the overlays, the plates are more vivid and attractive, when making overlays, we use colored enamels, which allow us to obtain various effects in metal overlays. Various types of fasteners, fittings for plates and metal plates are used: two-sided tape, a mustache for leather haberdashery, holes for riveting, sewing on clothes. All used fittings for plates, Schild, ensures a long product life.

In the manufacture of metal Schild, lining, our company uses modern equipment and technology, it can significantly expand the possibilities in the manufacture of lining. In the production of metal plates, only high-quality materials are used, advanced technologies and coatings in the manufacture of the plate, stamping, etching plates allow you to personalize the plates, produce nameplates and deliver to the market high-quality nameplates in the shortest possible time and optimal price.

Contact us! Mark, denote, present!

Shields, pads, metal tags to order Kiev from the Image Grad manufacturing enterprise, this is 100% quality, good mood and the key to your success!